In the world of wallpaper production, where precision and detail quality make all the difference, Instabilelab – a Made in Italy company specializing in interior decoration with wallpapers, fabrics, and rugs – has taken another step forward on its journey toward excellence.

To optimize its production process and ensure flawless wallpaper installation, the company has adopted the latest-generation Miura Katana automatic XY cutter.

This strategic choice has immediately delivered benefits in terms of visual quality, productivity, and operational reliability, as shared by Stefano Marin, Production Manager at Instabilelab.

A Turning Point

A Turning Point

“As a company, we are constantly striving for improvement, always looking for new technologies that help us deliver precision, quality, and consistency,” says Marin.

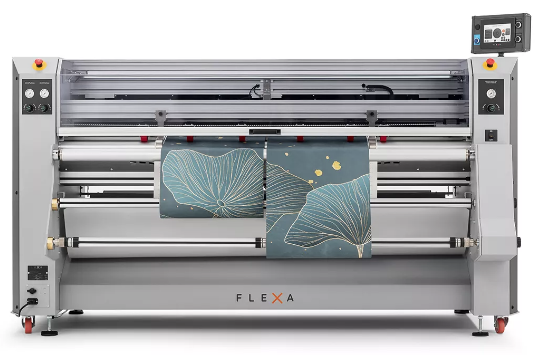

The push for innovation was also fueled by Fabrizio Da Frè, Flexa Italy Sales Manager, who introduced the Miura Katana – an innovative solution specifically designed to meet the needs of the wallpaper industry.

“Fabrizio guided us through a thorough evaluation, clearly explaining all the machine’s features and potential,” Marin adds. “At first, we were a bit hesitant – but we quickly changed our minds: the machine lived up to expectations from day one.”

No More White Lines

“The cutting quality is outstanding: the V shaped angled cut system completely eliminate the white lines between panels. This means installers no longer need to make manual touch-ups during installation, and the seamless wall effect is guaranteed.

Material handling has also improved: the dual rollers – front and back – keep the wallpaper taut, preventing wrinkles or imperfections. The cut is always straight, regardless of the material used.”

Absolute Cutting Precision

Until recently, the cutting phase required close operator supervision to ensure tolerances were met and to compensate for any print-induced material deformation. This added time and complexity to the process.

“With Miura Katana, all of that has changed,” Marin explains. “The precision is absolute from the beginning to the end of the roll. Tolerances have drastically decreased, and the result is always flawless, no matter the material.”

“With Miura Katana, all of that has changed,” Marin explains. “The precision is absolute from the beginning to the end of the roll. Tolerances have drastically decreased, and the result is always flawless, no matter the material.”

Easy, Fast, Intuitive

Installation and startup of the Miura Katana were quick and straightforward.

“After just one day of training with Massimo Vettorazzo, owner and president of Flexa, we were fully up and running. The training was clear and practical, and by the next day, the machine was operating at 100%.”

The user interface is intuitive, with guided steps and fast setup. The digital display of each cutting unit simplifies blade positioning, enabling quick startup and minimizing errors. The cut is always precise, with no need for constant adjustments.

A Recognized Leap in Quality

Miura Katana has enhanced not only production efficiency but, most importantly, the quality of the finished product.

“The cutter eliminates one of the most common issues during installation: white lines at the junctions. Today, the final result is flawless – installers no longer need to make any manual corrections.”

The official debut of this new technology took place at the international exhibition Salone del Mobile 2025 in Milan, where Instabilelab showcased a booth featuring high-ink graphics up to 5 meters tall, printed on various materials. The result?

Perfect walls, a seamless visual effect, with no visible white lines. The installation professionals didn’t even need to use a pencil – no touch-ups, no complaints.

Perfect walls, a seamless visual effect, with no visible white lines. The installation professionals didn’t even need to use a pencil – no touch-ups, no complaints.

Efficiency and Productivity

Beyond visual quality, Instabilelab also experienced increased productivity and optimized processing times.

“We work with rolls measuring 60–80 linear meters and can now cut them in around 15 minutes, compared to 20–25 minutes before – with fewer defects. Waste has been eliminated and inspections reduced, thanks to the consistency and reliability of the cut.”

The system is so stable that it allows continuous processing, with no need to pause for checks. From the beginning to the end of the roll, everything runs smoothly.

A Winning Choice

“We are proud to be the first in our industry to adopt Miura Katana,” concludes Marin.

“It’s a one-of-a-kind technology in today’s market. Flexa has proven to be a competent and supportive partner: Fabrizio guided us with professionalism, and Massimo provided outstanding technical support. In a word? An absolutely positive experience.”