“We first learned about FLEXCEL NX Technology from our sister company in Spain, so our CEO and Graphics Manager went to see firsthand the print quality it enabled. That, together with the type of polymer and unique patterning, convinced us right away to invest in a FLEXCEL NX System, which quickly replaced our previous platemaking system at Netpack’s premises.”

Gian Luca Zangheri, Graphics Manager of Italian packaging producer Netpack SpA, is recalling the events of 2016, and the company’s investment in a FLEXCEL NX System. Netpack“Since then,” he continues, “we’ve produced over 26,000 square meters of plates and moved every job to FLEXCEL NX Technology. We average around 1,500 new sets of plates a year and modify up to 1,000 sets. Now, we’re printing 100% of our work with FLEXCEL NX plates.”

The FLEXCEL NX System is housed in Netpack’s 15,000 m2 production plant in Cesena, in the Emilia-Romagna region of northern Italy. The company is part of the Sorma Group, which is particularly focused on innovation. Founded in 1973 by Nevio Lotti, Sorma pioneered a new approach to automation and mechanization in the fruit and vegetable industries that Emilia-Romagna is known for. Today the group designs and produces entire lines of automated post-harvest machinery, combined with technical packaging machinery, in its production plants in Spain, Turkey and the US.

The FLEXCEL NX System is housed in Netpack’s 15,000 m2 production plant in Cesena, in the Emilia-Romagna region of northern Italy. The company is part of the Sorma Group, which is particularly focused on innovation. Founded in 1973 by Nevio Lotti, Sorma pioneered a new approach to automation and mechanization in the fruit and vegetable industries that Emilia-Romagna is known for. Today the group designs and produces entire lines of automated post-harvest machinery, combined with technical packaging machinery, in its production plants in Spain, Turkey and the US.

Strategic decision

Netpack SpA born from Sorma’s need in 1984, the result of a strategic decision to expand beyond machinery into printing and assembling materials for fruit and vegetable packaging, for Sorma customers at first but eventually also for customers of its machinery’s competitors. Over the years, Netpack has created many innovative approaches to packaging fruit and vegetables; a notable example is the ‘Vertbag’, which combines a printed band providing ample space for brand communication with a net that displays the product and keeps it fresh.

A further strategic decision that sets Netpack apart from its competitors is to handle 100% of the packaging production cycle inhouse, from graphic design to finished products. “It gives us the total control that we need in order to guarantee the high levels of customer service that we’re known for.”

What his comment means becomes clear when Gian Luca explains the advantages having FLEXCEL NX Technology inhouse: “We can create plates that precisely match the characteristics of each job, taking into account the press, substrate, inks, and so on. In addition, being able to directly monitor on-press performance during start-up allows us to optimize and linearize production. And, of course, we’re not dependent on the schedules of external suppliers — which matters a lot if we have to remake a plate. We usually have plates ready within 48 hours of the customer confirming the order.”

Main benefits on press

Asked what major benefits Netpack has been enjoying after almost a decade working with FLEXCEL NX Technology, Gian Luca says: “Although it was the outstanding quality of the plates that first interested us, what’s truly remarkable is the overall efficiency and on-press performance that come with the quality. The tools and targets embedded in the plates simplify linearization of the process, and repeatability is excellent — we can remake plates for a repeat job six months later, with total confidence that we’ll get exactly the same result.”

He adds that the multi-form surface patterning from Miraclon delivers several benefits: “Printing speeds are faster, ink laydown and coverage are better, and minimal dot gain gives higher definition in halftones, fine text and detailed graphics. And, because ink transfer is more uniform on solids, it’s much easier to reach the required density.”

Solving fluorescent issues

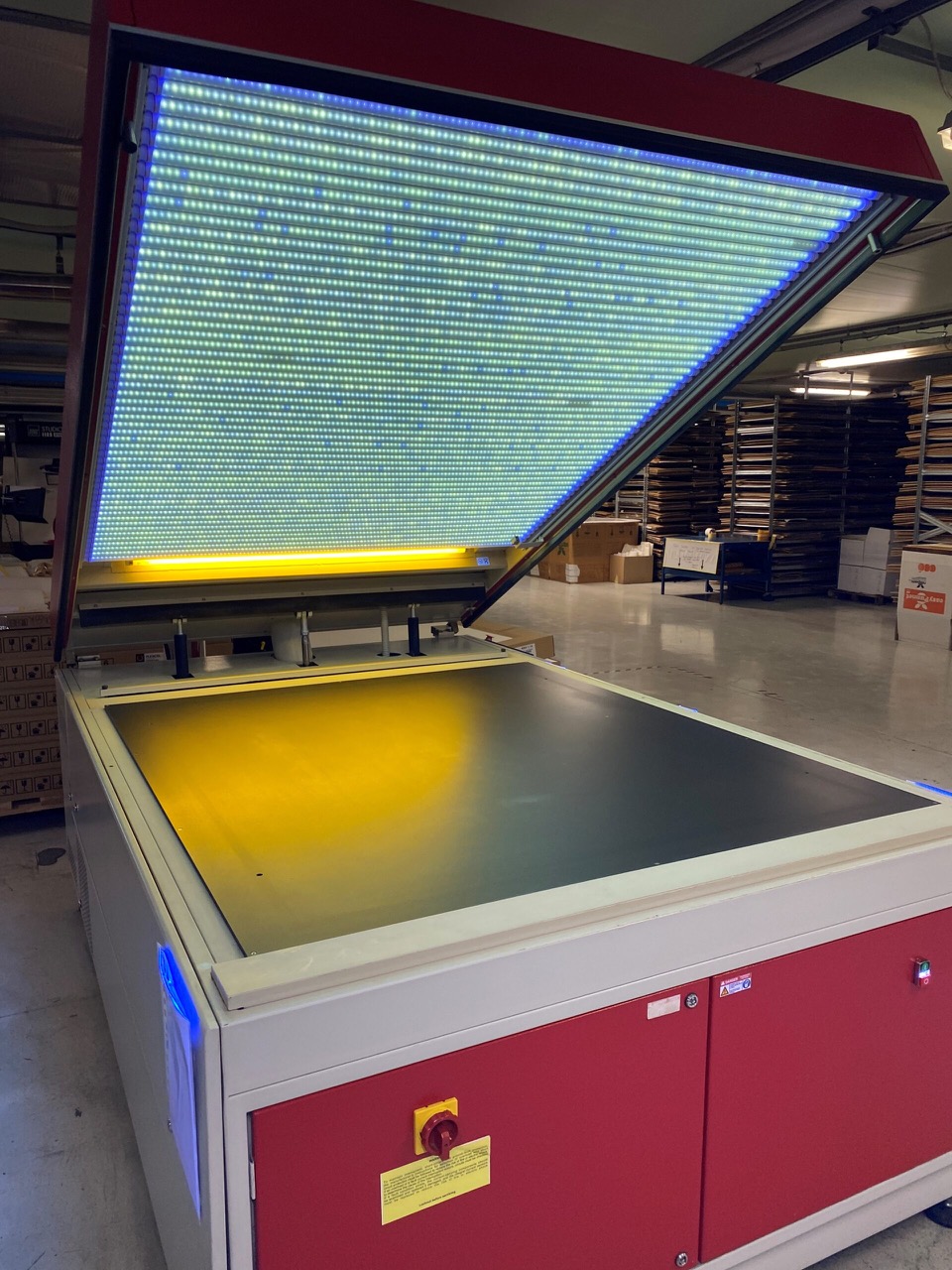

The company’s recent investment in a Shine LED Lamp Kit, innovated by Miraclon, has solved the increasing problems Netpack experienced with fluorescent exposure. Explains Gian Luca: “The main issues of fluorescent bulbs are well-known: limited tube life; variable power output, tube to tube, and within the same tube; longer exposure times; and high energy consumption. But on top of these, the overall quality of tubes has gradually declined, and it’s harder to buy acceptable replacements.

The company’s recent investment in a Shine LED Lamp Kit, innovated by Miraclon, has solved the increasing problems Netpack experienced with fluorescent exposure. Explains Gian Luca: “The main issues of fluorescent bulbs are well-known: limited tube life; variable power output, tube to tube, and within the same tube; longer exposure times; and high energy consumption. But on top of these, the overall quality of tubes has gradually declined, and it’s harder to buy acceptable replacements.

“To manage these issues, we needed strict controls and continuous adjustments in exposure times and other parameters. If we replaced a tube, it often took us half a day to position the lamps in order to achieve the best possible uniformity — which still wasn’t optimal, as less light would reach the edges. This resulted in variations in the polymer floor thickness and inconsistencies in halftone density.”

Winner of two FTA Awards (for Innovation and Sustainability) and a DFTA Sustainability Award, the Shine LED Lamp Kit consists of new LED UVA Lamps, supplied on a prewired bracket that can easily be retrofitted to existing fluorescent exposure frames. Shine LED Lamps are compatible with a wide range of third-party exposure frames.

Fitting the kit to an existing exposure frame, says Gian Luca, “has solved all the issues we had with fluorescent. Installation was every bit as fast and simple as Miraclon said it would be — the engineer started in the morning and by the afternoon we were producing plates, including calibration. Now we have perfect exposure uniformity, lower energy consumption, extremely long lamp lifespans, shorter exposure times due to the instant warm-up, and constant power output over time. Plates are consistent in floor thickness and exposure — which wasn’t the case before — and we’re 100% confident in the linearization of the plate production process.”

“The prepress team is also more productive,” concludes Gian Luca. “Quality controls are simpler, faster and less frequent — those time-consuming checks are a thing of the past. We do one check in the morning, one in the afternoon, and a monthly power check. Our operators now have more time to focus on other, more important things, enabling us to continue moving forward as a business!”