Lino Sistem, managing LinoGroup’s operations in Türkiye, is leading the transformation of the printing industry through digitalization, sustainability, and advanced engineering solutions. We spoke with General Manager Emrah Korugan about the future of Türkiye’s printing industry and Lino Sistem’s role in shaping it.

What is Lino Sistem’s strategic role and vision?

As Lino Sistem, we are LinoGroup’s strategic representative in Türkiye. Our corporate vision is to go beyond simply supplying products, to become a solution partner that guides the industry through digital transformation, shares knowledge, and increases our partners’ efficiency. Our goal is to combine global know-how with local needs to develop a Türkiye focused on advanced technology production.

How did you adapt your international vision to Türkiye?

How did you adapt your international vision to Türkiye?

Considering the dynamism and production power of the Turkish market, we strive to integrate global technological expertise with local realities. By tailoring aspects such as training, financing models, and after-sales support to local conditions, we make global technologies accessible and sustainable. This way, our international vision has evolved from a mere imported concept into a business model that grows in Türkiye.

What transformation does Türkiye’s printing industry need?

Today, the greatest needs of our sector are data-driven management approaches and environmentally friendly production models. At Lino Sistem, we play a guiding role in this transformation. With the solutions we offer in labels, packaging, and industrial printing, we both increase production efficiency and help meet sustainability goals.

Which technology has stood out recently?

The Durst RSCe inkjet printing systems have been one of our most popular solutions this year. They elevate the industry’s standards in both production speed and quality. Additionally, Elitron’s corrugated board and carton cutting solutions enable innovative and high-volume productions, particularly in advertising and promotional sectors.

How do your 2D and 3D solutions make a difference?

In 2D printing, we deliver speed, quality, and customization. In 3D printing, our Athens headquarters carries out real-time production using various 3D technologies such as Stratasys, Zeizz, Massivit, and Xjet, enabling large-scale object production without traditional molds. These technologies transform not only manufacturing but also design, marketing, and customer experience.

How is digital transformation managed in the label and packaging sector?

How is digital transformation managed in the label and packaging sector?

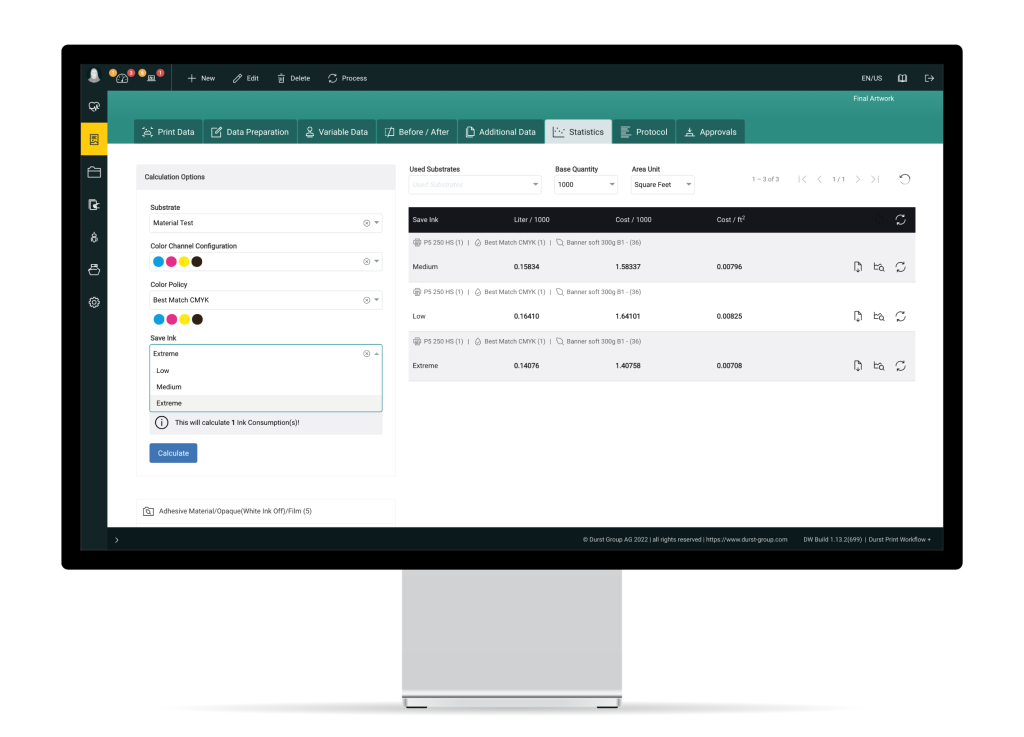

The label and packaging sector is one of the fastest to adapt to digitalization. With our partnerships with Durst and GM (Grafisk Maskinfabrik), we accelerate the digital transition in this area. We offer integrated solutions for short runs, customization, and variable data printing.

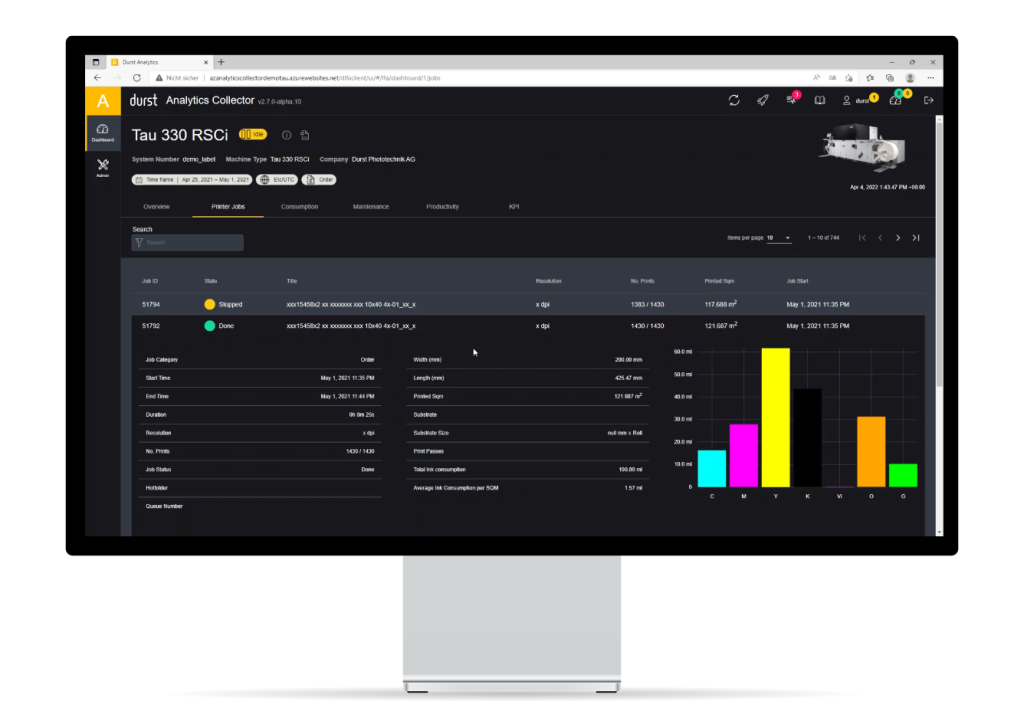

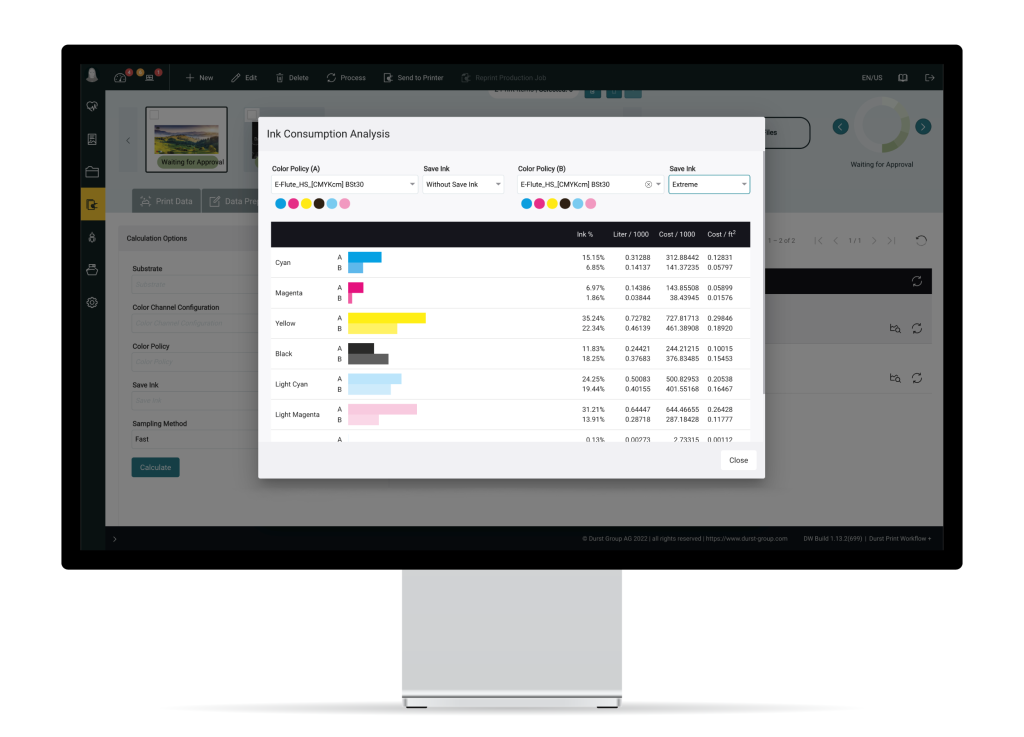

What do your “smart production” and “data-driven management” solutions include?

The software and automation solutions developed by the DURST and GM brands we represent enable real-time machine data monitoring, production reporting, and workflow optimization. This allows businesses to achieve more efficient production with less waste.

How do you differentiate in software, training, and after-sales services?

Through the Durst Academy, we provide continuous training to customers who need it and offer consultancy in software-supported production management. Our service network is widespread across Türkiye, providing fast and solution-oriented support. We don’t just sell hardware; we ensure that it is used in businesses with maximum efficiency.

How has customers’ perspective on technology changed?

In the past five years, our customers’ approach to technology has become far more strategic. They now focus not only on print quality but also on sustainability, production data, automation, and return on investment. We strive to manage this transformation with the right products and active communication.

What role does Türkiye’s operation play in R&D processes?

Although R&D activities within LinoGroup are primarily structured in the headquarters of the brands we represent in Europe, user feedback from Türkiye, demo results, and custom customer projects provide valuable data for product development. In this respect, the Turkish market plays an active role on the group’s innovation map.

How are your collaborations with international brands progressing?

How are your collaborations with international brands progressing?

Our collaborations with brands such as Durst, GM, and Elitron are long-term and strategically grounded. The Turkish market is a high-growth-potential, reference-worthy region for these brands. We position these partnerships not just as distribution but as regional technology hubs.

What do your sustainability policies include?

We actively contribute to sustainable production with energy-efficient systems, water-based and eco-friendly inks, and waste management solutions. Reducing the carbon footprint has now become an industry necessity, and as Lino Sistem, we are a structure offering leading practices in this field.

How are AI and IoT integrated into your products?

With the digitalization of production processes, IoT solutions now enable remote machine monitoring, automatic fault detection, and AI-driven production optimization. At Lino Sistem, especially through our Durst Digital InkJet printing solutions, we are pioneering this transformation in Türkiye. We actively implement these technologies through integrated software and digital dashboards.

How do you see the future of Türkiye’s printing industry?

We believe the future will be based on personalization, sustainability, and data-driven production. The Turkish printing sector, with its young, dynamic, and learning-oriented structure, has the potential to progress at the same pace as Europe. At Lino Sistem, we aim to lead this transformation.

In which sectors are you most active?

We operate in various fields such as labels, packaging, promotion, advertising, textiles, and industrial production. In the coming period, we are also working on developing specialized solutions for the food, pharmaceutical, and cosmetics sectors.

How do you shape your customer-specific portfolio?

How do you shape your customer-specific portfolio?

Each customer has different production capacities, sectors, and goals. That’s why we conduct needs analyses and offer the right combination of equipment, software, and training packages. We focus on flexible and modular solutions to ensure scalable investments.

What is your operational structure and service network in Türkiye?

From our Istanbul headquarters, we manage a nationwide technical service network. By keeping critical spare parts in stock, we ensure quick interventions and minimize downtime with remote support systems. Consumables and software support are also part of this structure.

How do your 2D and 3D solutions contribute to the industry?

Our 2D solutions provide high speed, low cost, and sustainability, while our 3D solutions facilitate large-scale productions.

Could you elaborate on your software integrations?

Durst, the brand we represent, develops software covering the entire process from prepress preparation to post-production reporting. These solutions, which can integrate with MIS/ERP systems, fully digitalize production processes.

How do your ink technologies ensure safety in the food and pharmaceutical industries?

We offer certified low-migration ink technologies specifically developed for the food and pharmaceutical industries. These inks are produced in compliance with international health and hygiene standards.

What is your strategy for sustainability and energy efficiency?

Sustainability must cover the entire production process, not just the product. Therefore, we develop low-energy consumption machines, recyclable packaging materials, and eco-friendly workflows. We support every investment to be optimized to reduce its carbon footprint.

Sustainability must cover the entire production process, not just the product. Therefore, we develop low-energy consumption machines, recyclable packaging materials, and eco-friendly workflows. We support every investment to be optimized to reduce its carbon footprint.

How are you preparing for Labelexpo?

For the Labelexpo taking place in September, we are preparing strong demo areas, new software and hardware launches, and Durst’s latest systems. We believe we will stand out at the fair with technological innovations and financing models that will attract particular interest from Turkish manufacturers.

What are Lino Sistem’s future plans?

In the coming years, one of our strategic goals is to quickly and accurately deliver the software and data analytics developments made by the brands we represent—particularly in UV InkJet and digital printing—to our end users.

Could you share a success story unique to you?

In 2024, as Lino Group, we implemented a project with a food manufacturer that reduced label production times by 40% and minimized production errors. By integrating the Durst RSC platform with software, we increased both print quality and cost efficiency. This project directly contributed to our customer’s growth in the export market.