The main goal of PrintLED srl is offering greener printing systems and technologies in order to extend environmental sustainability to printing processes. PrintLED UV LED systems are fully designed and manufactured in Italy with a modular concept, taking into account the importance of ease of maintenance. This design enables minimum downtime both during the installation of the system and during assistance. We asked more details to their CEO Francesco Dattilo.

Can you tell us about PrintLED and the brand, your business and what you offer as technology?

PrintLED® (registered trademark of PrintabLED srl) was founded in 2011; today it is a young, innovative company specialized in the design, manufacture and sale of systems based on UV LED technology for curing inks and varnishes used in the printing industry completely designed and produced in Italy.

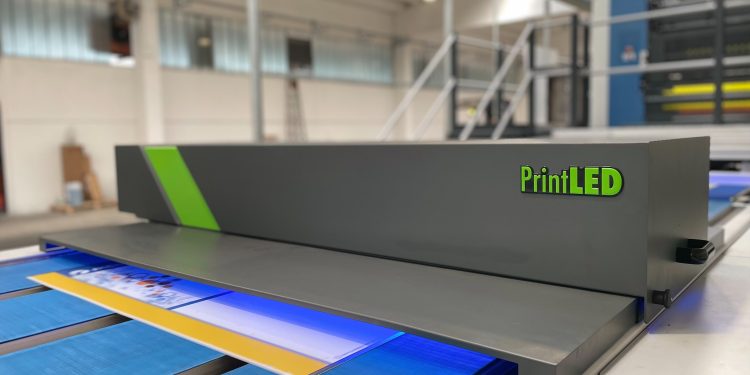

PrintLED is among Italian leaders in this new sector and already has more than 130 UV LED installations in Italy and Central Europe, and main applications are: Metalprint, Sheetfed Offset, Screen printing and Flexo.

For the quality of our products and the extraordinary efforts of our team, already in 2017, PrintLED has been awarded with the first innovation prize at Metpack, in Germany, the largest exhibition in the metal packaging sector.

Like all industry also in printing industry, sustainability and low electricity consumption are at the forefront for production. At this point, what are the main and prominent features of your company offered to the sector?

In many aspects the introduction of UV LED technology is environmentally friendly and contributes to cleaner and more sustainable life quality (significant Lower CO2 footprint of printing process) With PrintLED UV LED solutions, electric energy consumption can be reduced up to 80% compared to traditional Hg UV systems.

The heat waste is 80% lower than in conventional printing (IR) and traditional Hg UV PrintLED UV LED systems are completely Ozone and Mercury free (this complies with requirements from UN Minamata 2013 convention about elimination of Mercury).

Our solutions allow for up to 80% less production scraps thanks to better control for the operator of printing parameters. Furthermore, we can guarantee a significant reduction of Solvents in the UV LED inks/varnishes compared to conventional systems.

Last but not least, PrintLED UV LED systems are built with up to 90% recyclable materials.

PrintabLED can help companies to be more sustainable. More and more companies, especially in Europe, are presenting Corporate Social Responsibility Report and for many corporations the Sustainability Report will be mandatory by January 2026. PrintLED solutions help companies to achieve sustainability goals according to the Agenda 2030. Clear messages coming from the market show growing preference towards eco-friendly products, along with stringent regulations regarding the use of green products. Market studies forecast high-growth prospects of UV LED curing technology in new applications and preference for UV LED technologies in traditional applications, such as label print and packaging.

PrintabLED can help companies to be more sustainable. More and more companies, especially in Europe, are presenting Corporate Social Responsibility Report and for many corporations the Sustainability Report will be mandatory by January 2026. PrintLED solutions help companies to achieve sustainability goals according to the Agenda 2030. Clear messages coming from the market show growing preference towards eco-friendly products, along with stringent regulations regarding the use of green products. Market studies forecast high-growth prospects of UV LED curing technology in new applications and preference for UV LED technologies in traditional applications, such as label print and packaging.

The UV LED cured printing market witnessed significant growth in recent years, driven by the increasing demand for high-quality and sustainable printing solutions. UV LED cured printing offers various advantages such as instant drying and faster curing time, increased productivity, excellent adhesion of the ink, resistant to fading, less energy consumption (up to 80% less than traditional UV lamps), no ozone, mercury and UVC, reduction of CO2 emissions, greater safety for the workers as the UV LED lamps operates below 50°C, less stress on the machines and therefore less maintenance. The UV LED cured printing market is dynamic, driven by various factors, including changing customer preferences, technological advancements, regulatory landscape and industry collaborations. This market is quite competitive with several players involved in research, development and manufacturing, but the level of experience of the producers of UV LED systems can greatly affect the quality of the products and results obtainable.

Some far-east players are focusing only on lowering the price of the solutions and installations offered, delivering average-quality, and non-customized products as if all the printing machines were the same. The reality is that every single solution has to be designed and developed according to the customer’s specifications, it has to be “Taylor made” in order to offer the best possible and longlasting outcomes.

In PrintabLED, we started studying, designing and producing print UV LEDs, over 10 years ago, much earlier than many competitors (some may have been on the market for longer, but they have started producing LEDs only recently).

Every year PrintLED invests a significant portion of its income in research and development, often collaborating with universities and research institutes to continuously improve performance, availability and reliability at state-of-art level.

Our systems each year acquire about 100,000 hours of real operational “experience” and information, which we collect from our customers. Thanks also to this, our knowledge of UV LED systems progressively increases every year. A major part of our production process consists in selecting the LEDs, which are not all the same! The LEDs are produced by silicon semiconductors that can differ significantly. We carefully select them based on the characteristics of light power emission, energy consumption and wavelength emitted to better meet the customer requirements.

Our systems each year acquire about 100,000 hours of real operational “experience” and information, which we collect from our customers. Thanks also to this, our knowledge of UV LED systems progressively increases every year. A major part of our production process consists in selecting the LEDs, which are not all the same! The LEDs are produced by silicon semiconductors that can differ significantly. We carefully select them based on the characteristics of light power emission, energy consumption and wavelength emitted to better meet the customer requirements.

In the selection of LEDs and in the design of the systems applied to the machines, we always try to work by optimizing the consumption of the LEDs themselves, but we also pay attention to the performance of the system, sustainability, energy saving, and so on.

What are the advantages of choosing UV Led systems for businesses? What are the prominent differences of the system you provide when you compare with traditional UV?

UV LED curing systems as designed by PrintLED allow considerable advantages versus UV Hg traditional technology:

• reduce electricity consumption by over 80%

• reduce times and costs of the production process

• reduce maintenance cost and unplanned downtime of the press

• improve the operational flexibility of printing allowing broader variety of supports

• based on application, it could also increase the production capacity of the press

• improve the quality of the printed products.

We expect that sooner rather than later, once regulators will have appreciated the benefits of UV LED technology, it will be decided for elimination of mercury lamps

Can you tell us about your brand’s position in the sector and your goals in the short, medium and long term at home and abroad?

Can you tell us about your brand’s position in the sector and your goals in the short, medium and long term at home and abroad?

Italian has been for Printabled a fantastic playground, because many “pioneering” clients decided to test the UV LED technology from the earliest time, despite all uncertainties related to availability of inks and coatings. As Printabled was developing its first generation of dryers, the early adopters helped pushing the demand for high quality consumables.

Today Printabled has a strong reputation in the number of installed references, in its ability to evolve and to improve its products and in client proximity. The position of Printabled in the Italian market is being also noticed outside of Italy, and generating a fast-growing number of leads and projects also in Europe and beyond.

Will there be innovations that your company will launch in the remaining period of 2023?

We are working on some interesting and important news to widen the range of applications. We will hear more about PrintLED in the next few months…

What is the importance of Labelexpo for your company? What are your solutions that you will exhibit to your visitors at Labelexpo and Istanbul Packaging fair?

We will exhibit at LabelExpo Europe next October, our stand is Hall 7Stand D25 and also at Istanbul Packaging Fair we will attend at 2nd Hall 205B booth.

You will meet our sales representatives who will show you how PrintLED UV LED solutions allow you to optimize the printing process in a simpler, more constant and more sustainable way.

Anything you want to add or highlight?

Anything you want to add or highlight?

We see somewhere and somehow a sort of hesitation from clients that are reluctant to adopt the new technology. Return of investment as calculated looking only at energy saving and cost of inks and coatings is not providing the full picture (please consider that in some markets, distributors of consumables tend to put premium price to UV LED specific materials).

There is a long list of additional benefits that can be of interest of the clients and are difficult to evaluate in money, but are all concurring in the same direction of going towards a faster payback.

You may want to contact Printabled team for more information and gather additional elements from the experience of Printabled Customers. And for Turkish Market you can get in touch with our Sales Manager Canan Doğan Nalbantoglu, [email protected].