Leading Indian trade shop Veepee Graphic Solutions (‘Veepee’) has added to its world class flexo platemaking facilities with the installation of three new plate imaging and exposure units from Esko.

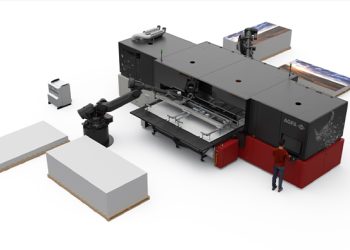

The prepress and premedia specialist has added the Esko CDI 4260 plate imager and XPS 4260 and XPS 4835 plate exposure units to its Bangalore facility, as part of a move to strengthen its business through offering superior quality plates.

“Veepee operates its entire platemaking infrastructure on Esko workflow software and is already fully HD Flexo certified, achieved through consistently producing the highest quality plates for its customers,” explained Karan Talwar, Esko Sales Director for South Asia. “In a market characterized by challenging conditions, Veepee faced a significant dilemma. With the selling price of processed plates in the region on a continuous downward trend, placing immense pressure on their profitability, the team made the strategic decision to prioritize superior quality and service for their clients.

“To keep pace with growing demand, Veepee has now invested in a further three Esko hardware solutions to boost its platemaking capabilities,” he said. “The combination of Esko prepress software and plate manufacturing hardware delivers the superior quality plates that their customers have come to expect,” said Karan. “The CDI produces plates that are perfect for all print applications that require high print output and stability on press, while the XPS – with its front and back LED UV arrays – ensures consistent quality plates while also reducing energy use and waste.

“Unlike UV frames, which use light bulbs with fluctuating output, the XPS uses UV LEDs which don’t need warm-up time and always emit consistent light,” he said. “This simultaneous and optimally controlled UV main and back exposure produces highly consistent digital flexo plates. This innovative offering not only addressed the customer’s need for enhanced quality, but also allowed them to differentiate themselves in the market.

“Additionally, we have replaced their aging, end-of-life flexo CtP systems with the advanced CDI imager, ensuring that Veepee remained at the forefront of technological innovation.”

Veepee Graphic Solutions Managing Director Jaichandra Peethambaram said that the new Esko XPS system will be installed at their unit in Sri Lanka, and the CDI and XPS will be installed in their upcoming facility in India in order to deliver the consistent and quality plates on which they have built their success.

“For almost 30 years, Veepee Graphic Solutions has consistently embraced cutting-edge technologies across all facets of our operations,” said Mr. Jaichandra. “With strategically located facilities spanning four different regions in India and Sri Lanka, we are dedicated to producing top-notch flexo plates and delivering against our commitment to establish new industry benchmarks for service levels and quality assurance.

“These new Esko solutions ensure that we can meet all those objectives, while delivering the optimum quality and customer satisfaction that helps us secure our future success,” he said.